NV-Pro

Cross laser 3D sensor

Outstanding environmental resistance

Easy operation with robot teach pendant

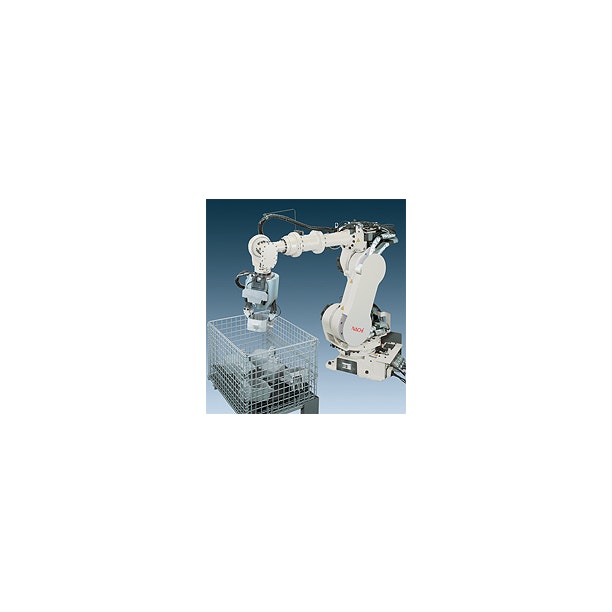

Bulk handling

Distinction of parts

Measurement

Product Inspection

NV-Pro

by Nachi

High-speed, high-capability systems

- A visual device has been imbedded and unified with an AX control device, realizing high-speed processing. (Measuring Time (compared to conventional devices of our company): 2D: 60%, 3D: 83% increase in speed)

- Equipped with a part search tool which is not affected by the direction, size or exterior irregularities of parts.

Equipped with stereo recognition function

- Uses our independently developed stereo vision algorithm to measure the 3D position of work. Even for bulk work within the pallet, the robot performs position offset and removes work.

Cross laser 3D sensor

- Cross laser irradiation makes it possible to recognize the tilt, height and holes of work in 3D position. Optimal for removing bulk sheets and boxes.

Outstanding environmental resistance

Environmental resistance has been increased 4 times through the automatic exposure function. Able to stably ascertain work even during changes in brightness.

Easy operation with robot teach pendant

- Uses the same operation interface as the AX control device. The robot teach pendant can be used to perform simple operation for all visual devices, including condition settings and programming.

- A separate display is not required. Camera images can be displayed in color on the teach pendant, realizing compactness and easy operation.

Specification

| Item | Specifications | |

|---|---|---|

| Image Input | Supported cameras | Black & white: 640 (W) x 480 (H) (Maximum black & white: 1600 (W) x 1200 (H)) |

| No. of connected cameras | 4 | |

| Measurement Conditions | No. of registrations | Maximum 999 |

| Exposure time | Setting possible/automatic control* | |

| Lighting | Selection possible | |

| Retry | Yes (modification of exposure conditions is possible) | |

| Search range | Adjustable range through combination of rectangle and oval | |

| 2D | Probe analysis, rotation search | |

| 3D (optional) | Stereo, cross laser | |

| Measurement | Measurement start method | Robot program function |

| Offset amount calculation method | ||

| Offset method | World coordinate standards/flange coordinate standards | |

| Peripheral Equipment | Operation | Operation using teach pendant |

| Data storage | Compact flash | |

| I/O signal | Trigger input: 8 points Lighting/laser control output: 16 points |

|

| Environment Conditions | Surrounding temperature | 0 - 45°C |

| Surround humidity | 20% - 85% (no condensation) | |

*Depending on the camera used, it may not be possible to perform automatic control and settings for exposure time.

(*1) The specifications are subject to changes without notice.

(*2) In case that an end user uses this product for military purpose or production of weapon, this product may be liable for the subject of export restriction stipulated in the Foreign Exchange and Foreign Trade Law. Please go through careful investigation and necessary formalities for export.